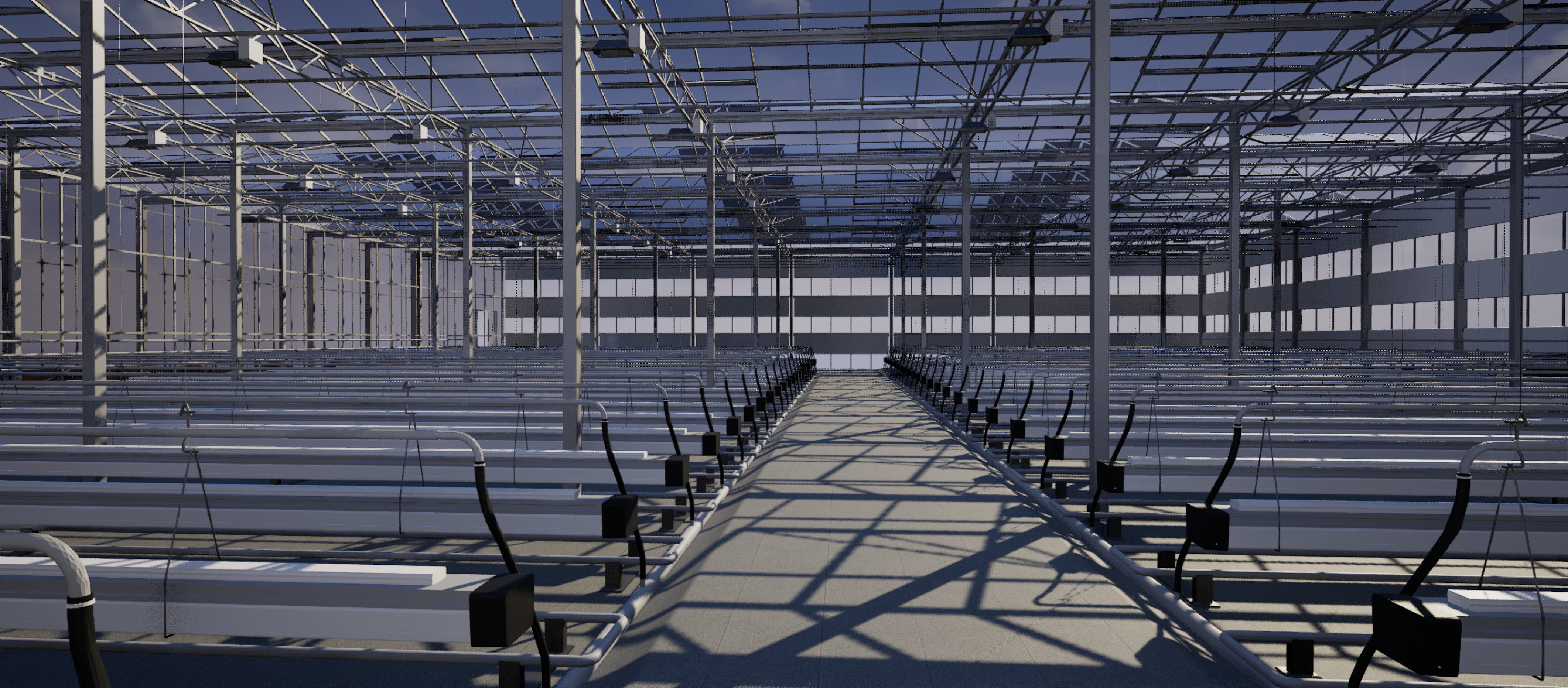

In commercial greenhouse, heating is accomplished by circulating hot water through steel pipes, which is heated in a central boiler room. For large-scale greenhouses, this heating approach is highly efficient as it guarantees a consistent temperature across the entire greenhouse area, regardless of its size.

This uniformity creates consistent growth conditions for plants, resulting in uniform growth rates, appearance, and crop quality. Maintaining a consistent temperature is essential to ensure that the produce appears uniform and grows simultaneously.

Various fuel sources can be used for greenhouse heating, such as coal, wood, natural gas, fuel oil, or electricity from thermal power stations, among others. However, despite the numerous alternative heating options, natural gas continues to be the favored and appealing choice for several reasons.

The primary and most significant reason is the release of carbon dioxide, which is essential for plant photosynthesis. When energy-efficient systems are used in the greenhouse, gas consumption decreases, resulting in substantial cost savings for the company as there is no need to acquire it in a liquid state.

The second factor is the comparatively affordable equipment costs. Boilers and alternative heating systems, when employed on an industrial scale, typically come with much higher price tags compared to gas-based equipment. Furthermore, the maintenance of gas equipment is simpler and more cost-effective.

The growing areas within greenhouse are divided into climatic zones. Such division of the growing area into heating contours allows for the even distribution of heat and the creation of a consistent microclimate. Consequently, this enables the harvesting of a consistently high yield of quality produce from the entire area.

The control of heating zones is managed via a central computer system through manifolds on the heating circuits. The quantity and type of circuits are determined by the climate and the specific crops being grown, with the main circuits being as follows:

Snow heating

This circuit is used to warm up the accumulated snow above the gutters of the construction, and the resulting melted snow is directed away through the stormwater drainage system.

Monorail heating

This circuit is used as an extra heat source in the upper area of the greenhouse.

Underbench heating

It is used to heat growing benches or tables.

Tube rail heating

This serves as the primary circuit for heating the greenhouse. Moreover, it functions as transport tracks for service trolleys.

Crop heating

The crop heating is associated with heating in the plant growth area. This circuit provides warmth to the vicinity of the plant roots to prevent excess moisture that may lead to diseases.

A well-designed heating system allows for maintaining a temperature with a maximum fluctuation of 1°C across the entire greenhouse area, whether it's 1 hectare, 5 hectares, or 10 hectares in size.

CONTACT NOW

HEATING IS KEY FOR THE MICROCLIMATE IN THE GREENHOUSE

Heating is the primary factor that shapes the microclimate within a greenhouse. In turn, the microclimate determines all the processes of plant formation and yield, from seeding to the end of fruiting. The availability of the right amount of heat defines the season and the periods during which you can harvest.

Before selecting a heating system, it's crucial to decide which crops you plan to grow. Different crops require different temperatures for comfortable growth. The average temperature range to maintain in a greenhouse is 15°C – 25°C.

There are two main types of heating: air and water heating. Both types are used in farm greenhouses.

ADVANTAGES OF CENTRALIZED HEATING

Lower fuel consumption compared to air heating.

Cost reduction through the use of alternative fuels.

Possibility of remote (mobile) and computerized control.

Even distribution of heat throughout the greenhouse.

Ease of maintenance.

DISADVANTAGES OF WATER HEATING

The main drawback of solid fuel boilers is their relatively long warm-up time. Depending on the boiler's manufacturer, the type of fuel used, and the size of the greenhouse, it can take from thirty minutes to one and a half hours for the temperature to reach the desired levels, which is quite long for plant cultivation. In this case, it's necessary to anticipate sudden temperature changes and control the heating "proactively."

Logistical issues, storage, and the purchase of quality fuel material also present challenges. It's important to find a reliable supplier who guarantees high-quality, well-dried, and energy-efficient products.

The combustion of solid fuel produces ash. Consider this when positioning boilers, to prevent ash from settling on the greenhouses and shading them.

The type of fuel used for this heating method can vary - coal, wood, gas, fuel oil, wood chips, etc. Gas is considered the most convenient fuel. Its use requires minimal maintenance, and the carbon dioxide produced in the boiler room can be used by plants for active photosynthesis.

Nevertheless, there's growing popularity in using versatile solid fuel boilers that operate on wood, wood chips, pellets, etc. The fuel for these boilers is accessible, making them simple and economical to use.

When utilizing universal boilers, it's recommended to implement an automatic fuel feeding system. It's worth noting that in practice, it can be challenging to find responsible workers who would monitor fuel consumption and timely load the furnace.

When utilizing universal boilers, it's recommended to implement an automatic fuel feeding system. It's worth noting that in practice, it can be challenging to find responsible workers who would monitor fuel consumption and timely load the furnace.

Monorail heating.

This circuit is used as an additional heat source in the upper part of the greenhouse.

Under-bench heating.

Used for heating shelving systems.

Tube-rail heating.

This is the primary circuit used for delivering heat throughout the greenhouse. Additionally, this circuit serves as transport rails for service carts.

"Plant growth pipe," i.e., heating in the plant growth zone. This circuit heats at the root level to remove excess moisture, which could lead to disease.

Centralized heating is typically used in operations that grow high-profit products, such as tulips or leaf lettuce on automated lines. Air heating is less expensive to install, but the fuel consumption is higher. Central heating, on the other hand, requires more initial investment but is more economical in use.

Unlike industrial-scale operations, in commercial greenhouses, the uniformity of temperature takes a back seat. Often, farmers must sacrifice the quality of the product to reduce costs and decrease investments.

ADVANTAGES OF AIR HEATING

Quickly heats up the greenhouse. The heating speed is measured in minutes, which most favorably affects the growth of the produce.

Air circulation provides comfortable conditions for plants and reduces the likelihood of air stagnation, which can lead to mold.

By installing two or more heaters, you safeguard against unexpected breakdowns. If one heater fails, the others will be sufficient to at least put the plants into dormancy and survive the critical period.

You can purchase a versatile heater that can operate as a fan without heating during the summer. It facilitates air movement and makes the climate more comfortable when it's hot.

DISADVANTAGES OF AIR HEATING

A significant disadvantage of such heaters is the relatively high gas consumption and uneven heat distribution. However, there's a solution for the latter: the use of polyethylene ducts.

For small greenhouses, to achieve an even microclimate, polyethylene ducts with holes are used. The holes are made smaller closer to the heater and larger further away from it.

This approach helps to even out the distribution of outgoing heat and carbon dioxide along the length of the duct.

INFRARED RADIATION

It's worth highlighting a "classic newcomer" on the market – infrared radiation. Infrared heaters are often referred to as "solar warmth." But is this accurate? What exactly is this type of heating? Let's delve into it in the context of their use in greenhouses.

Infrared radiation is part of the electromagnetic spectrum, lying between visible light and microwave radiation. Following the analogy with the sun's warmth, the principle of the sun's thermal radiation involves the sun's heat warming the surface of the water, earth, trees, etc. In turn, the heated surface absorbs the heat and then releases it into the air. In a greenhouse, the principle works similarly: infrared heaters are placed close to objects and heat them – plants, tables, chairs, etc. Once the objects are heated, they release the excess heat into the air.

The main argument for their use is the reduction in costs for infrared heaters and ongoing expenses. Moreover, these heaters are easy to install.

DISADVANTAGES OF INFRARED HEATING

The wavelength differs from that of the sun. The sun provides energy necessary for photosynthesis, which IR lamps do not.

Infrared lamps heat only what is directly exposed to them, meaning plants on the periphery may not receive the necessary warmth.

Installing IR heaters directly above plants can obstruct natural light, essential for plant photosynthesis.

The use of fans to circulate air is necessary. Without fans, air stagnation can occur, leading to mold development.

Uneven temperature distribution along the length of the tube. The longer the tube, the less uniform the heat distribution, which can lead to uneven plant growth. Only some manufacturers incorporate a special film in the heater to even out heat distribution along the length of the lamp.

The maximum heating temperature is 500°C, requiring lamps to be placed close to the plants.

In conclusion, we've outlined the main types of heating. You may encounter various offers for new systems; however, these innovations are not yet widely used in greenhouses. Any of the listed types is a viable solution; the key is to understand your objectives and what specifically suits your needs.